TALKING TEXTILES

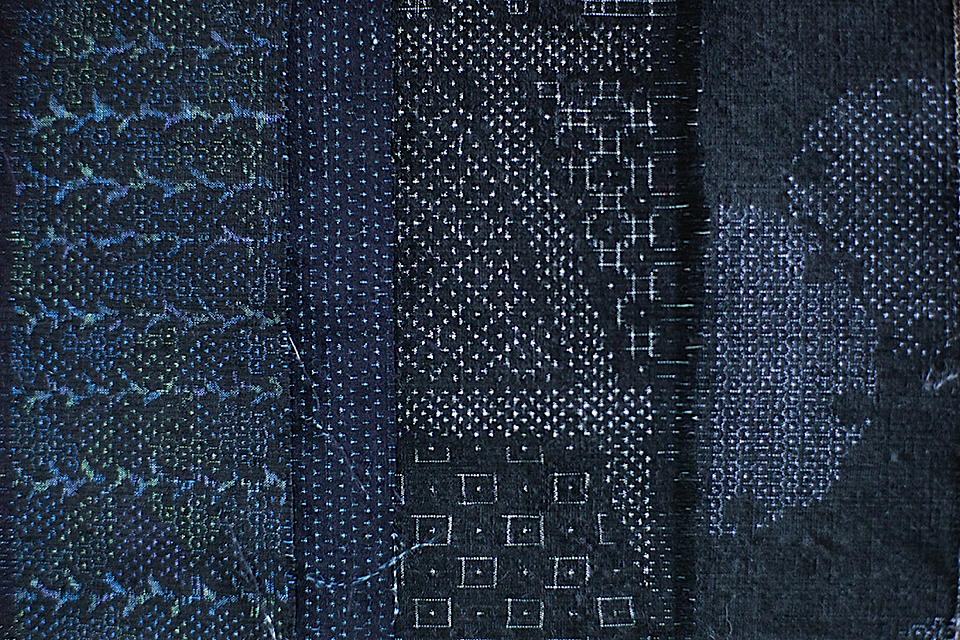

a legendary japanese silk

photo Christian Aschman

The Japanese fabric Yuki-tsumugi is used to make fine-quality kimonos and has a 2,000 year history in Japan. Making the cloth requires more than 40 procedures, each needing the handiwork of a skilled craftsperson. These skills have been passed down through the years, and in 2010 the Yuki-tsumugi production technique was inscribed on Unesco’s Representative List of the Intangible Cultural Heritage of Humanity.

OKUJUN’s fabrics have a beautiful luster, exceptional lightness, and rich texture. Supreme Yuki Silk is a fabric of highest quality produced by a method descended from the traditional technique and Yuki Silk is a new fabric that preserves the fine texture but made with a more efficient production process.

The secret of the incomparably soft texture of the silk resides in its raw material — floss silk, and the untwisted yarn spun tenderly by hand from floss silk while typical silk yarn is produced by tightly twisting together several filaments from separate cocoons.

Yuki-Tsumugi, silk fabric production technique is very complex.

The high quality fabric is a result of the artisans’ highly skilled hand craftsmanship. The fabric is woven from delicate hand-spun yarn, and is a layered masterpiece of skilled hand-craftsmanship from artisans who execute all the needed procedures. It is supported by a sophisticated combination of professional instinct and dexterous artistry, nurtured through long specialized practice. A single piece of cloth is born from the hands of many master artisans.

Floss silk is obtained from a cocoon and, with the use of a tool, gently stretched by hand into yarn, without spinning. During the process, sizing is applied to strengthen the delicate yarn.

By using a traditional back-tension loom called a jibata, the hand-spun yarn is woven into cloth while applying minimal tension to the yarn. The warp is tied to the weaver’s hip and inseparable from the loom, the weaver controls the tension of the warp through the movement of the hip while weaving. A Hia shuttle used to store weft yarn- made from an oak tree, and an osa -reed-are used to tighten the weave, to create a fine woven silk fabric.

Finally, after the process of sun drying, a cloth that is light, warm and extremely soft is born.

www.okujun.co.jp

www.christian-aschman.com

photo chritian aschman

photo chritian aschman

photo chritian aschman

photo chritian aschman

photo chritian aschman

photo chritian aschman

photo chritian aschman

photo chritian aschman

photo chritian aschman

photo chritian aschman

photo chritian aschman